Classic and Vintage Auto Restoration Parts

Thousands of Parts for Classic Cars and Trucks

Welcome to Collectors Auto Supply, your one-stop shop for everything classic car restoration! We specialize in providing enthusiasts like you with the finest classic car parts, vintage car parts, and classic auto parts available, including top-quality replacement weatherstripping, seals, and interior parts.

Founded in 1992, our passion for keeping the classics rolling and helping people with their restorations drives our commitment to providing enthusiasts with the finest restoration parts available. Whether you're searching for classic vehicle parts, auto parts for classic cars, or vintage auto parts, we cater exclusively to the needs of classic car enthusiasts seeking hard-to-find parts to bring their restoration to completion.

Whether you're restoring a timeless beauty or a rugged classic truck, we have the parts you need to complete your project with confidence. Our user-friendly Year Make Model vehicle search ensures a seamless shopping experience, allowing you to effortlessly find the perfect parts tailored to your specific vehicle. Say goodbye to endless searching and guesswork – with Collectors Auto Supply, finding the right classic auto parts and convenience go hand in hand.

Struggling to locate that elusive vintage car part?

Let our knowledgeable team assist you. We love helping people find the right part for their vehicle. Reach out to us through chat, phone or email (contact page), and we'll promptly provide the expertise you need.

With over 30 years of experience and more than 100,000 satisfied customers, Collectors Auto Supply stands as a trusted authority in the world of classic car restoration. Our dedication to old-fashioned values means that every interaction is characterized by integrity, reliability, and a commitment to excellence. Embrace the essence of classic car restoration with Collectors Auto Supply – and let us help you bring your project to completion.

Most Popular Products

-

MSRP: $134.08 - $149.38$113.97 - $126.97

MSRP: $134.08 - $149.38$113.97 - $126.97 -

Roof Headliner for Ford F100-F250 Truck 1973-79 2DR PickUp Black Cardboard

MSRP: $139.96 - $149.38$118.97 - $126.97 -

Hood Insulation Clip for 1966-1971 Plymouth Fury Metal Unpainted Front 1 piece

MSRP: $83.49$70.97 -

Hood Insulation Clip for 1967-1992 Chevrolet Camaro Unpainted Front 1 piece

MSRP: $81.14$68.97 -

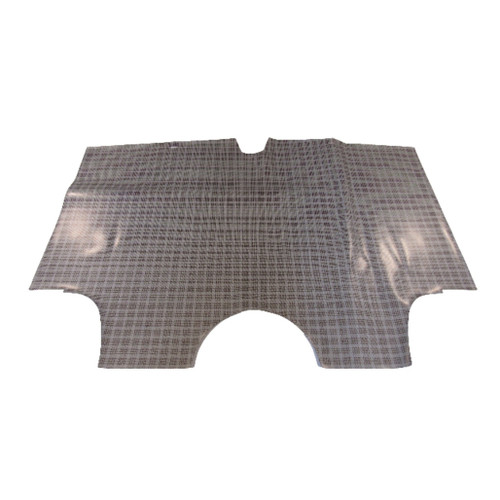

Headliner ABS Kit for 1940-1947 Ford Truck ABS Plastic With Sail Panels

MSRP: $575.26$488.97 -

Headliner ABS Kit for 1965-1966 Ford Truck Black ABS Plastic

MSRP: $461.14$391.97 -

Hood Insulation Clip for 1965-1999 Cadillac Calais DeVille Plastic Large Square

MSRP: $81.14$68.97 -

Headliner ABS Kit for 1962-1967 Ford Econoline 5 Window ABS Plastic

MSRP: $477.61$405.97 -

Hood Insulation Clip for 1966-1971 Dodge Coronet Metal Unpainted Front 1 piece

MSRP: $83.49$70.97 -

Cowl Panel Clip for Toyota FJ Cruiser 2007-2014 8pc Precision CFK-2652-07

MSRP: $45.85$38.97